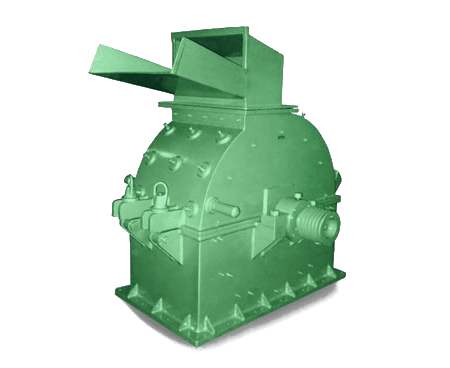

Standard Mill Accessories / Parts

Hammermill complete with Feed Hopper, Set of sideliners, Topliners, set of the main shaft assembly, set of Bar type Hammers, Screen Frame, Set of 3 Nos. Perforated screen and V - pulley for the mill.

Save upto 50% power consumption compared to traditional disintegrators.

Call to know more

Feed Material passes through a wide feed hopper into the grinding chamber.

Call to know more

The swinging hammers, in rotating hammer rotor, crush the materials before.

Call to know more

Hammermill is subjected to rigid final inspection and actual grinding tests at our experimental station.

Call to know more

| Permissible Feed Size | Up To 100 mm |

|---|---|

| Fineness Achievable

| Upto 80 Mesh Or 180 Microns |

| Permissible Hardness | Upto 3 Moh’s Scale |

| Permissible Brittleness | Medium To High

|

| Permissible Moisture

| Up To 3% |

Hammermill complete with Feed Hopper, Set of sideliners, Topliners, set of the main shaft assembly, set of Bar type Hammers, Screen Frame, Set of 3 Nos. Perforated screen and V - pulley for the mill.

Mounting Accessories: M.S. mounting structural frame without legs / M.S. stand complete as per our standard supply with outlet caller for air balloon, discharge outlet, facility to mount mill and motor, set of cross-type slide rails, set of V-Belts, and set of air balloons with clamp, V-pulley for Motor and safety guard for drive.

Electrical Accessories: Branded Electric motor for main drive, suitable starter D.O.L. / Star Delta type semi-automatic & Ampere meter for load Indication.

Dyestuff. Pigment & Colour, Chemical. Foodstuff, Spice. Bakery & Confectionery, Agro, Ayurvedic Roots & Herbs. Pharmaceutical, Dehydrated Fruits & Vegetables, Tea, Cosmetic, Glass, Plastic, Bakelite & Resin, Mineral, Ceramic. Rare Earth Metallic Ore, Coconut Shell, Cattle Feed. Tobacco. Snuff. Woodchips. Coke and Many other...

| Model | ROTOR DIA

(mm) |

CHAMBER (Width) |

Machine (RPM) | HP (R) | RPM (R) | L (O-DIA) | W (O-DIA) | H (O-DIA) |

Capacity KG/HR UPTO |

|---|---|---|---|---|---|---|---|---|---|

| HM - 6 | 1050 | 650 | 1200-1400 | 75/100 | 1400 | 1500 | 1200 | 2000 | 15000 |

| HM - 5 | 900 | 550 | 1400-1600 | 60/75 | 1400 | 1300 | 1000 | 1600 | 10000 |

| HM - 4 | 750

| 450 | 1800-2000 | 50/60 | 1400 | 1100 | 900 | 1350 | 7500 |

| HM - 3 | 600 | 360 | 2000-2200 | 30/40 | 1400 | 900 | 800 | 1000 | 4500 |

| HM - 2 | 450

| 300 | 2500-3000 | 25/30 | 2880 | 800 | 700 | 850 | 1200 |

| HM - 1 | 450 | 220 | 3000-3500 | 15/20 | 2880 | 800 | 600 | 850 | 750 |

| HM - 0 | 300 | 200 | 4000-4500 | 7.5/10 | 2880 | 550 | 400 | 650 | 300 |

| HM - Mini | 250 | 150 | 4500-6000 | 3/5 | 2880 | 460 | 350 | 530 | 150 |