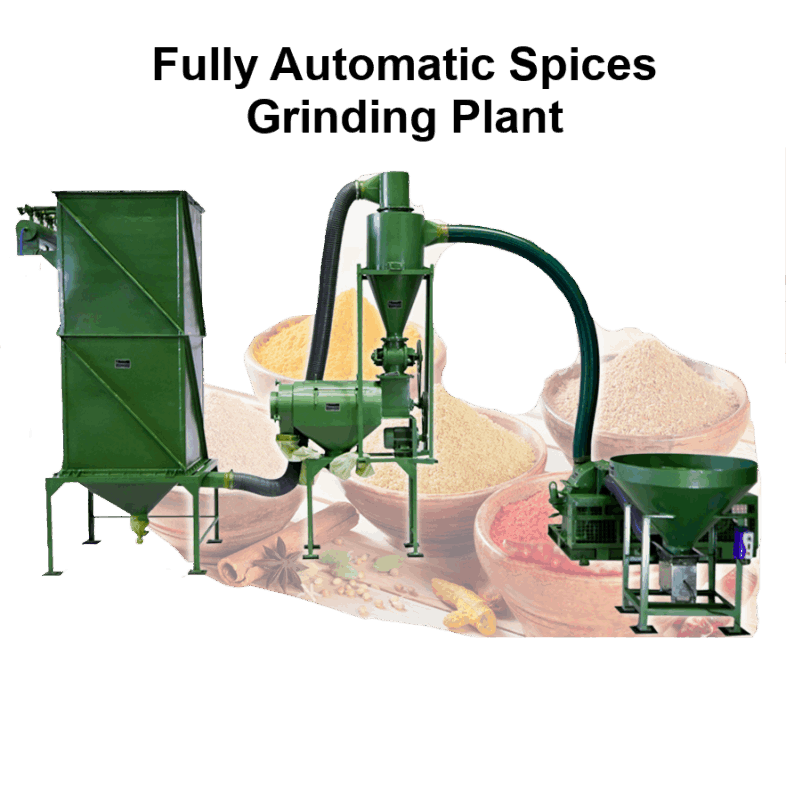

+2500 SUCCESSFUL INSTALLATIONS

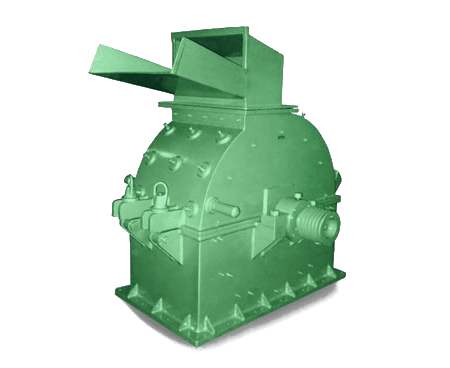

Even the smaller (25kgs/hr) grinding mills by Yagnm saves upto ₹ 7 lakhs* annually by reducing wastage. Get output in single attempt. No need to grind multiple times to get fine output. Designed for efficiency & better economics.